- Homesteading

- Project Portfolio

- Pearls Place

- Footings

Footings

Pearls Place needs a foundation; Big Foots and Sonotubes

With a budget this small, the foundation of the project has to save as much money as possible; Big Foots with Sonotubes to hold the concrete make the most economical sense for footings. We're all about spending less money, even though the Big Foots are expensive to start with.

After excavating the holes, these are put into place, leveled and then back filled; then they have to be inspected before back filling and pouring the cement.

High embodied energy, the cost of creating and shipping any product, is by necessity high in concrete. Not only does the powder have to be manufactured, but the product itself, mixed concrete, has to be transported from the supplier to the site.

As it's heavy, and needs to be constantly mixed, the cost of the trucking can sometimes exceed the cost of the actual concrete.

You'll always have too much, because unless it's batched, or mixed right on site, the supplier sends a little extra to make up for faulty calculations or miscommunications.

Always have a few pieces of poly film and some boards ready to make a step or pavers with the extra so it doesn't go to waste; if you don't use it, the driver of the concrete truck will usually find a convenient culvert that requires a bit extra on the edge, or simply dump it over the bank, sometimes in exactly the wrong spot.

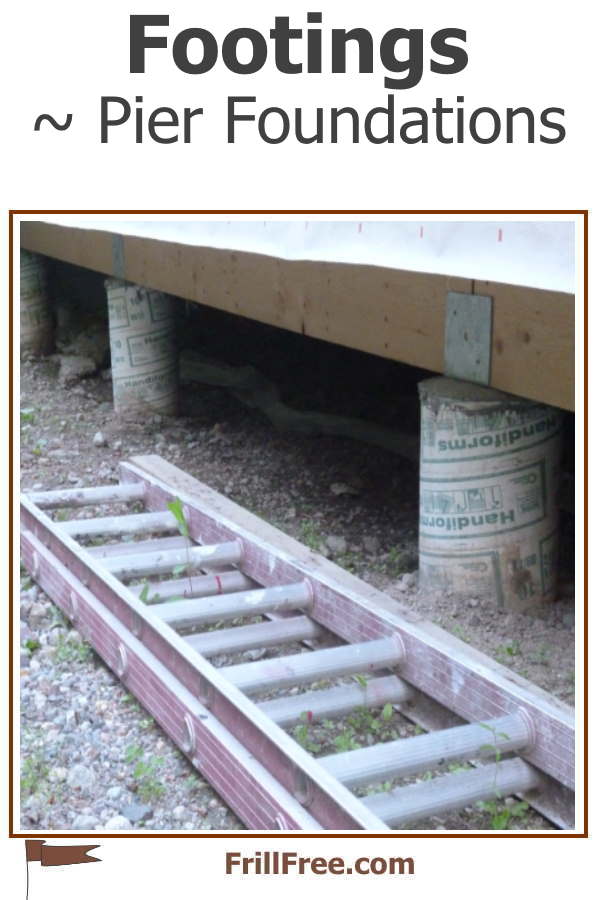

Footings - sonotubes are very economical and easy to use

Footings - sonotubes are very economical and easy to useWe decided to use the pier foundation for our tiny house project because of the lesser amount of concrete needed.

The concrete for perimeter footings and crawl space walls would be more than ten times more, require the rental of plywood forms (or the even pricier Styrofoam forms) and more time to set.

Here's how we excavated and poured the footings;

Buck checks out the backfilled Big Foots with Sonotubes showing - these will be cut off at the same level (by running a string line).

Buck checks out the backfilled Big Foots with Sonotubes showing - these will be cut off at the same level (by running a string line). Will this rain ever stop? You can't pour into wet Sonotubes so each of them is protected by an upside down bucket.

Will this rain ever stop? You can't pour into wet Sonotubes so each of them is protected by an upside down bucket. We're as ready as we'll ever be; bring on the concrete!

We're as ready as we'll ever be; bring on the concrete! A two man crew, with one woman following along with a long piece of rebar to get the bubbles out is about the right number of workers.

A two man crew, with one woman following along with a long piece of rebar to get the bubbles out is about the right number of workers. An upside down Big Foot makes an excellent funnel for pouring the cement into the tube (and the buried Big Foot).

An upside down Big Foot makes an excellent funnel for pouring the cement into the tube (and the buried Big Foot). The corner footing made us very nervous as it was right on the edge of the excavation for the water line. Lots of bracing made it more secure.

The corner footing made us very nervous as it was right on the edge of the excavation for the water line. Lots of bracing made it more secure. Troweling off the excess prevents any moisture from pooling and provides a way for water to drain off the top.

Troweling off the excess prevents any moisture from pooling and provides a way for water to drain off the top.Each concrete pier had a metal bracket or saddle installed to hold the main beam.

One more hurdle out of the way; fingers crossed, now we wait for 24 hours to let the concrete set up.

Concrete is a funny material; it requires age to cure, and there's no hurrying it. After ten days, the forms can be stripped to ground level, but with so many other jobs to do, this might wait until the structure is completed.

Tip:

This kind of footing, known as piers, pier foundations or stilts, is sometimes not accepted by insurers, even though it's an acceptable and approved method from a building inspectors viewpoint.

Make sure you are able to get insurance coverage!

Next; the beams and floor joists...