- Homesteading

- Project Portfolio

- Pearls Place

- Roof Trusses

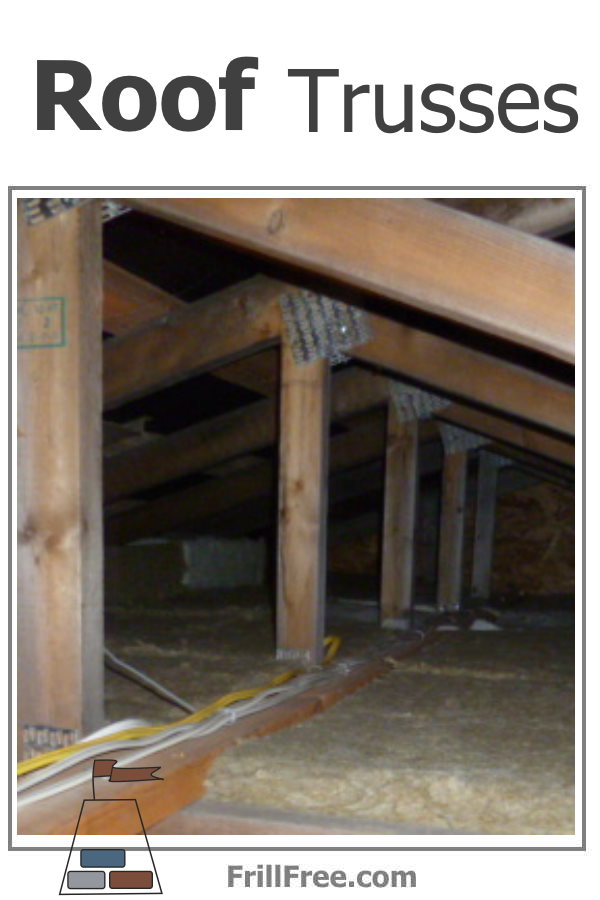

Roof Trusses

Engineered for snow load and other live loads

We've had these trusses for a long time, just waiting for the right project - they were engineered, locally built and out of local wood too.

We had a good crew, almost too many people, but everyone wanted to be a part of this crucial step in the construction of Pearls Place.

Everyone had a part; Tammie swept the cobwebs and pine needles off the trusses after Rick and Gord brought them over to the site; John observed the safety regulations and gave directions, Terry straddled the top of the wall with skill and total lack of fear, Mike instructed the crew when to bring the next truss and Pierre tackled the attachment of several pieces of bracing.

As each one goes up, it is plumbed and measured so as to be even and straight, because the next part of the roofing process depends on it. If any part of the roof is slapdashed together, the rest of the roof is harder to install.

Although it was fraught with some tension, and Mike had to walk away and breathe for a minute or two, eventually the trusses were all in place to the satisfaction of all.

Everyone wants to get in on the act...roof truss installation is so exciting!

Everyone wants to get in on the act...roof truss installation is so exciting!The crew and volunteers showed up in droves for this part of the project - I think the gorgeous weather had something to do with it.

The first truss in place...

The first truss in place...The first truss is the most important. If it's out of plumb and not level, it will take a lot to get the rest in line, and the metal roof will be impossible to fit properly.

Pretty much all on, the trusses make this project look more like a house...

Pretty much all on, the trusses make this project look more like a house...It's taking shape now, and looks more like a house every step of the way.

What a long day; rain in the forecast, so bring out the tarps!

What a long day; rain in the forecast, so bring out the tarps!Take your time, just focus on right now so no-one gets hurt, and it all comes together.

There's more to be done; bracing and getting the roof ready for roofing...

There's more to be done; bracing and getting the roof ready for roofing...The roof still needs work; in the foreground you can see 2x4's for the strapping, and the long sheets of metal roofing that will keep out the rain and snow.

Some of this is best done without a big crew. Sometimes finding things for people to do is hard, so scheduling it out ahead of time works well.

Then you call the crew back to assist with the metal roofing, because going up and down ladders or trying to put up the sheets and make sure they have the correct overhang is an exercise in frustration.

For now, tarps have to do that job, with rain in the forecast they'll be called upon to keep the wet from the floor that is tongue and groove OSB. Watching that swell up in the rain is not a thing we want to do.

The completion of this part of the project brings a great deal of satisfaction. Many thanks to the crew and volunteers for all they contributed to this.

See the progress on the roof next...